The Social Bites Way

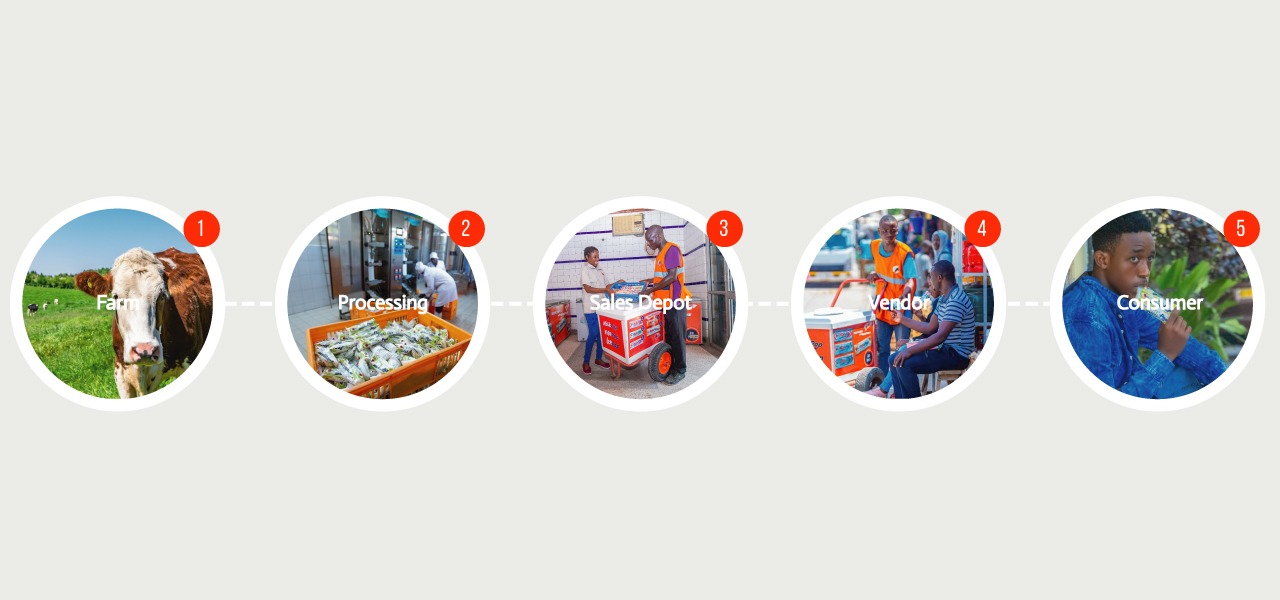

From farm to consumer

Your everyday quality meal

By ensuring affordability and easy access to our products, we make sure that many Kenyans are able to enjoy our frozen delights. For us, the experience that our customers have with our products and brand matters a lot. We are driven by a focus to give our customers great quality, and we strive hard to make this shine through every part of our operation. We have control over the supply chain from sourcing of milk to production and blast freezing of the products through to the sales of the product by the Vendor in the street.

Testing the milk

The testing of the milk starts at the farm level where the raw milk is sourced from local farmers. Here the raw milk is subject to a variety tests including organoleptic and gravity testing. Only the milk that meets our standards is collected and transported to our processing facility. Upon receiving the raw milk at the platform and before any processing starts, it is subject to additional testing.

Quality matters to us

Made with care

We process the products at our new production facility with state of the art machinery. The processing is handled by our professional production team who are keen to ensure that every process is followed during the production.

Powerful freezing

After processing the products goes through a freezing process at the company’s impressive blast freezing facility. Here the products are exposed to temperatures of minus 35 degrees Celsius. The strength of the blast freezer makes sure that enough cold wind is circulated during freezing and ensures that the products become frozen while staying smooth and creamy.

Bagging in bulk

The bulk bagging of our frozen finished products happens immediately after blast freezing, at our packing line. This is the last process before products are stored in our cold storage pending dispatch to the market. At the packing line our dedicated employees are able to handle large volumes.

At the sales depot

We are passionate about quality. In our distribution setup our dedication to quality shows in how each of our Sales Depots are operated. We strive to operate our Sales Depots very professionally and we are very keen on processes both when it comes to product handling and how we interact with the Vendors.

We transact with the Vendors by the use of digital means thereby increasing transparency in our operations. At the Sales Depot we also train the Vendors and we go the extra mile to motivate them. We like to see them become excellent business people of their own. And we let them know that their appearance and image in the market matters a lot.

Always frozen

We ensure that product safety always stays a top priority. Both at the Sales Depots and in the market we have controls in place to ensure that we never compromise on the product quality of our frozen dairy products. We visit the Vendors in the market each day and we are able to support them in their quest to become better business people. We want to make sure that the consumers who buy our products from the Vendors always have a positive experience.